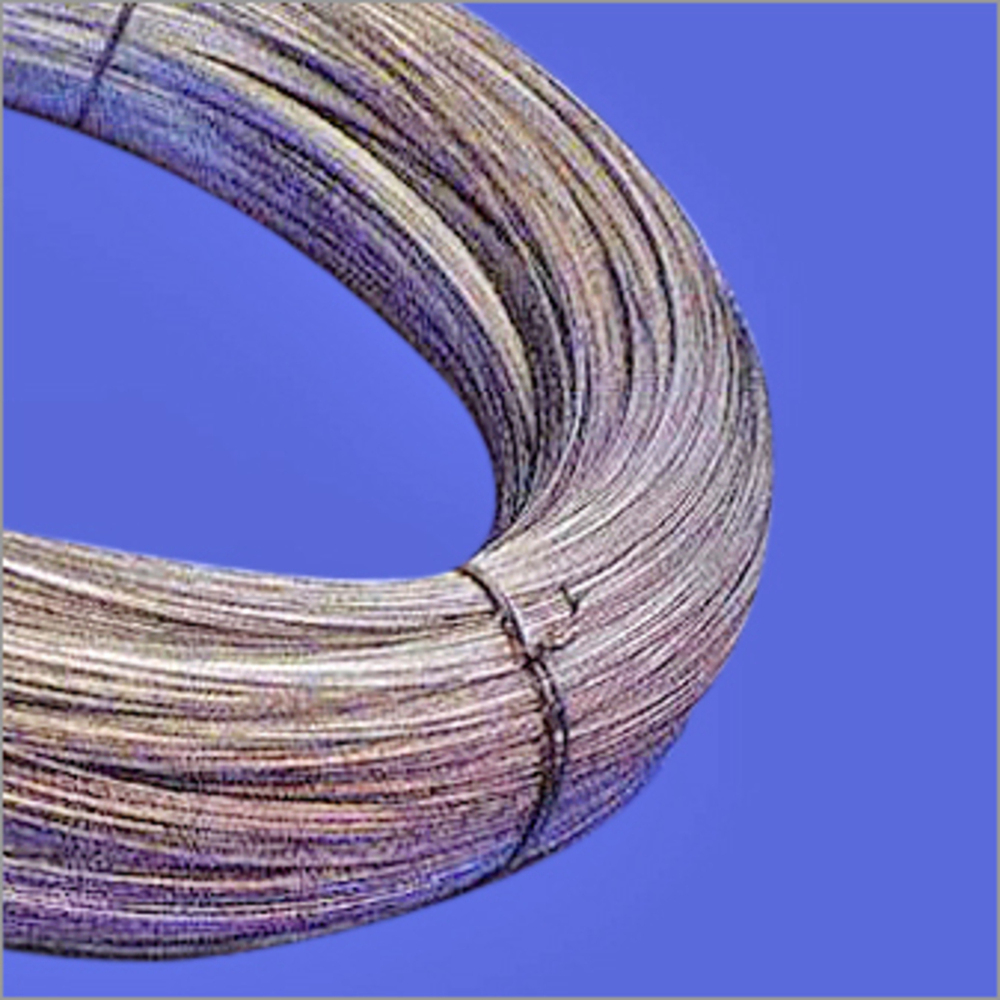

Earthing Coil

MOQ : 1000 Kilograms

Earthing Coil Specification

- Surface Treatment

- Galvanized

- Material

- GI (Galvanized Iron)

- Technique

- Cold Rolled

- Grade

- IS 319 / IS 1897

- Coil Thickness

- 1 mm - 2 mm Millimeter (mm)

- Coil Weight

- 1.5 - 2.5 Kg (Approx) Kilograms (kg)

- Coil Length

- 3 m - 6 m Meter (m)

- Hardness

- Full Hard

- Application

- Electrical Earthing System

Earthing Coil Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Supply Ability

- 100 Kilograms Per Day

- Delivery Time

- 1 Week

About Earthing Coil

The offered Earthing Coil is manufactured at vendors end using the best quality raw materials and sophisticated technology under the strict supervision of highly experienced technocrats. This coil is used in an earthing system for ensuring safety to several electrical appliances. The earthing system involves galvanized iron. Based on the depth of the earthing pit, the length of wire coil is form. In this process, the bottom layer and surrounding space are filled with charcoal, while the top layers and surrounding are filled up with loose earth. Many industries require earthing coil and to meet their demands, we deal in this product. Manufactured from top grade material, this product is used to give protection to electrical appliances and people against sudden electrical surge and electric shocks.Features:

- Resistant to abrasion

- Has perfect finish

- Rugged design

- Convenient to install

Premium Build for Longevity

This earthing coil is crafted from high-grade galvanized iron, ensuring resistance to rust and corrosion even in challenging environments. Its full hard structure and cold-rolled technique offer extra durability, making it ideal for long-term outdoor and industrial use.

Optimized for Versatile Applications

Designed for electrical earthing systems, the helical spiral coil adapts to diverse grounding scenarios. Whether you need reliable earthing for residential settings or demanding industrial environments, the coil delivers consistent performance, ensuring safety and compliance.

Quality Assured with Industry Standards

Manufactured according to IS 319 and IS 1897 standards, each coil is subject to rigorous quality checks. Galvanized surface treatment provides superior protection, while precise coil dimensions allow for easy installation and integration into existing systems.

FAQs of Earthing Coil:

Q: How is the earthing coil installed in an electrical earthing system?

A: To install the earthing coil, excavate a pit at the required location, connect the coil to the main grounding conductor, and place it securely in the pit. Ensure all connections are tight, and backfill with soil or a salt-charcoal mixture for optimal conductivity. Always follow recommended safety and electrical grounding guidelines.Q: What are the primary benefits of using a galvanized iron (GI) earthing coil?

A: The main advantages are enhanced corrosion resistance, increased longevity, and reliable electrical conductivity. The galvanized finish protects against rust and deterioration, making these coils suitable for long-term outdoor and industrial applications.Q: Where can helical spiral earthing coils be used?

A: These coils are ideal for outdoor, industrial, and residential grounding applications. Typical uses include substation earthing, building electrical grounding, lightning protection systems, and other situations requiring effective electrical dissipation into the earth.Q: When should I choose a coil with a wire diameter between 3 mm and 6 mm?

A: Selecting the appropriate wire diameter depends on the sites soil condition, current-carrying requirements, and regulatory standards. Thicker diameters are generally chosen for higher current loads or challenging soil environments.Q: What process is used to manufacture these earthing coils?

A: The coils are produced using a cold-rolled technique, ensuring uniform thickness and full hardness. Surface treatment with galvanization adds an extra layer of rust resistance and extends the lifespan of the product.Q: How does corrosion resistance enhance the performance of this product?

A: Corrosion resistance prevents degradation caused by moisture, soil chemicals, and environmental exposure. This maintains the coils conductivity and structural integrity, ensuring safety and consistent grounding efficiency over time.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

SURYA WIRES (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry